QUALITY & SAFETYQUALITY CONTROL

Strict Quality Control

To ensure product quality and safety, in addition to standard hygiene management at our factories, including manufacturing facility and equipment inspections, worker education, and various manufacturing process, raw material, and product inspections, we also conduct hygiene management conforming to HACCP standards. As part of additional safety and security measures, we employ a quality assurance system based on FSSC22000, the international certification standard for food safety management systems, to improve our product quality and services, and provide customers with satisfying products.

Kobe Factory

| FSSC22000 | |

|---|---|

| Certified factory | Kobe Factory |

| Certification number | JQA-FC0218 |

| Scope of certified activities | Design, development, and manufacturing of processed cheese, cheese food, dairy food products, and natural cheese |

Nagano Factory

| FSSC22000 | ||

|---|---|---|

| Certified factory | Nagano Factory | |

| Certification number | JQA-FC0166 | |

| Scope of certified activities | Design, development, and manufacturing of processed cheese | |

| FSSC22000 | ||

|---|---|---|

| Certified factory | Kobe Factory | Nagano Factory |

| Certification number | JQA-FC0218 | JQA-FC0166 |

| Scope of certified activities | Design, development, and manufacturing of processed cheese, cheese food, dairy food products, and natural cheese | Design, development, and manufacturing of processed cheese and dairy food products |

At the factory, we dismantle processing kettles and filler machinery daily for cleaning and sterilization to maintain constant cleanliness. Our factories also feature airflow design so that external air is taken in through filters and existing air is ventilated outside. This prevents entry by dust or insects.

Prior to entering the worksite, employees are required to change into designated work clothing and wear work boots, a hat, and a mask. Employees also use lint rollers for full-body dust removal and are required to wash their hands (disinfecting).

Furthermore, workers are also prohibited from bringing in metallic objects and accessories as part of measures to prevent foreign object contamination due to human error.

Reinforcing these systems enable us to provide our customers with safe and reliable products.

Quality Assurance System

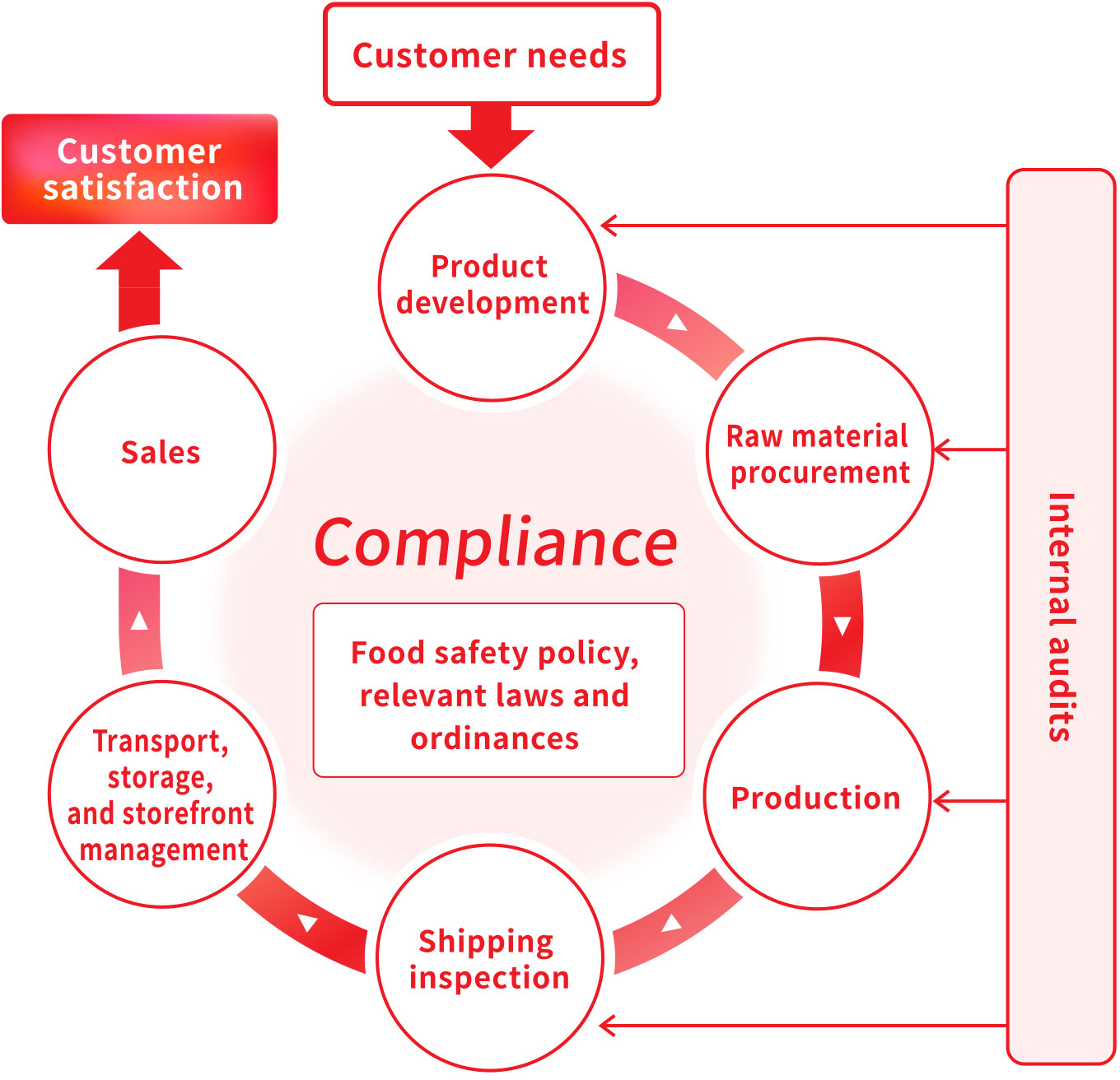

We increase customer satisfaction by engaging in product development and commercialization that reflects customer needs.

We have established a quality assurance system for ensuring our ability to provide safe and reliable products throughout our entire value chain, from product development to raw material procurement, production, distribution, and sales.

Product development

We evaluate potential products from a variety of perspectives, including design, labeling, expiration dates, manufacturing conditions, and packaging, to confirm product safety as well as environmental and legal compliance. These processes enable us to eliminate product risks before in advance.

Raw materials procurement

We only procure raw materials from suppliers that conform to applicable laws and ordinances, and that clear our strict standards for allergen and foreign object contamination countermeasures. We further implement acceptance inspections and factory audits to continuously confirm quality and safety.

Production

We conduct production in a clean environment and incorporate advanced technology to continuously conduct strict inspections. We have earned FSSC22000 certification, the international standard for food safety system certifications, to ensure a greater level of quality and safety.

Shipment inspections

We conduct numerous inspections, including inspections for microorganisms and chemicals, sensory inspections, and outer appearance inspections to ensure the quality and safety of the products we produce.

Transport, storage, storefront management

We cooperate with distributors to reinforce strict transport management and ensure products shipped from factories reach our customers under the appropriate distribution conditions.